Fan Blades & Impeller

WSK™ various design of wind blades available from100mm to 4m in diameter. Aerofoil blade designed like fix type,adjustable pitch angle type and wind genterator type for different applications.

Common blade materials are FRP, Anti-Static PP, AL alloy & GI.

Explosion proof electrical parts suitable for Zone 1 & Zone 2 available all under one roof. Flameproof pats like explosion proof swith box, explosion proof junction box, explosion proof cable gland, explosion proof lighting bulbs, explosion proof fluorescent lamp, explosion proof heater, explosion proof motor, explosion proof motor starter, explosion proof pipe connector, and many others.

The pneumatic flow fans are mainly design for high anti-hazardous classification areas. It uses the power from air compressor system to drive the air motor fan into high speed, hence giving air ventilation.

This pneumatic fan comes with various designs like the Floor stand type, Desk Top type, Square plate Wall-mount type, Portable type and Ceiling Hang 3-5 blades types. It an ideal ventilation equipment suitable for marine, vessel, offshore, battery room, oil & gas & petrochemical sectors.

The hydraulic axial flow fans are mainly design for high anti-hazardous classification areas. It uses the power from fire system to drive the fan into high speed, hence giving air ventilation.

It an idea ventilation equipment suitable for marine, vessel, offshore, battery room, oil & gas & petrochemical sectors.

Explosion proof air-conditioning units and heat pumps are suitable to be used in Class 1, Zone 1 & 2, Group CD hazardous environment. Design available in Window unit, Split wall mounted, Floor standing type, Offshore window aircon unit, Ceiling cassette & Ceiling mounted. Further optional operating features like corrosion coating extended to cabinet, coil & fins can be done upon request.

Electrical supply: 110V / 1phase, 230V / 1phase, 400V / 3phase, 50/60Hz.

UK FANKER™ has been the market leader in providing Explosion Proof fan blower suitable to be used in Hazardous areas. There are many available designs to suits different applications, like Axial fan, Square plate wall mounted type, Centrifugal blower, Roof extractor, Oscillating wall fan, Floor standing fan and others.

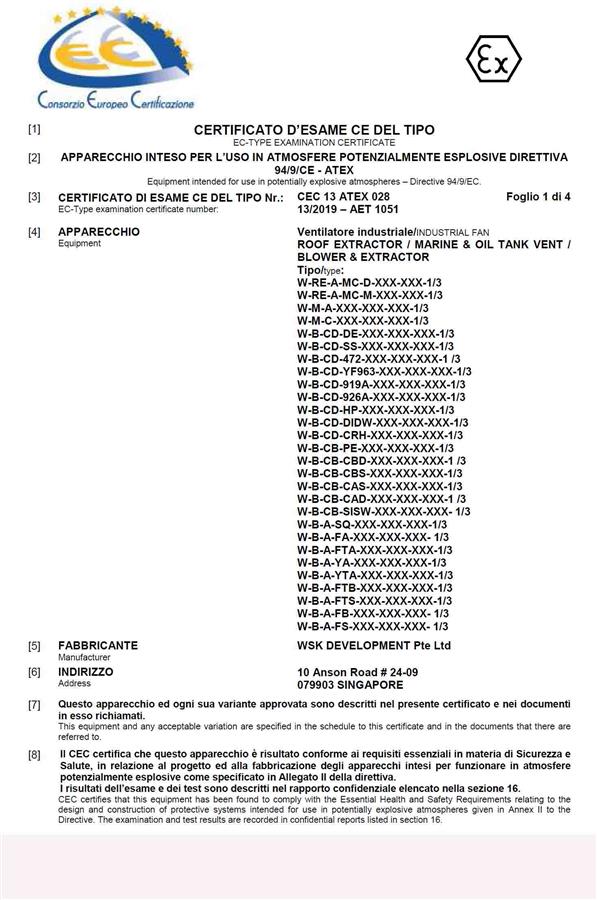

Our fans are all complied to International Explosion Proof Standards, mainly like IECEX, ATEX 94/9, BASEEFA, BS, UL & AS. Conformance to Class 1, Zone 0, 1, 2, IIB / IIC, T1 – T6, Group A, B, C & D.

Light weight portable blower adopts the die cast aluminum alloy blades with gradual twisted airfoil cross section. It features high wind flow and wind pressure. Electrical voltage available in 110V, 220V and 380V, with 50/60 Hz. Blower end can easily fitted on with flexible hose. It is suitable for air extractor or fresh air supply, for locations such as underground, warehouse, tunnel, marine cabin, ship, lab, etc…

WSK high pressure blowers are available in mild steel paint coated finishing or stainless steel casing and impeller. It is commonly use in applications where high resistant require to over come in the system.

Most comes in direct driven design using high speed motor.

Capacities to 11,000 CFM, 27″ SP.

FANKER™ has played a leading role in the manufacturing of chemical blowers made from anti-corrosive and chemical resistant plastics, suitable for corrosive environment. It fan casing is made from thermoplastics materials such as PP, FRP or PVC. Fan impellers are also available in thermoplastics materials or steel with FRP coating. As similar with normal centrifugal blower design, chemical blower can be direct driven or belt driven, depend on different applications and capacities. FANKER™ UK also design roof ventilator using FRP and PP materials as requested by the market.

Capacities to 80,000 CFM.

UK FANKER™ has offered wide range of centrifugal blower designs for different applications to the industries. Standard blower body is made of mild steel with epoxy paint coat finish, GI sheet, Stainless Steel and FRP. It blower wheel designs available in forward curve, backward curve, plenum, radial and paddle. Motors are all at the minimal enclosure of IP 55, Class ‘F’ or Class ‘H’ insulation which are complied to international standards like IEC, ATEX 94/9, IECEX, BASEEFA, BS & AS. Explosion proof for hazardous areas Zone 0, I, II, IIB or IIC, are available upon request.

Capacities to 300,000 CFM.